Insights

Sourcing Sustainably

TOO X Do Not Go Gentle

15/04/25

This week we are sharing our team’s monthly inspiration all about ways we can do better when specifying in design and with our workshop learnings, highlighting what to consider in the world of material circularity and sustainability.

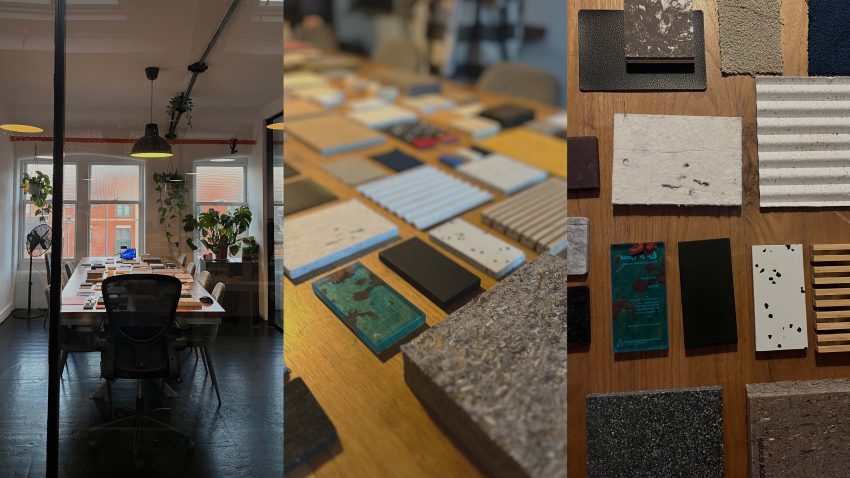

Last month the 3D retail design TOO team attended a workshop in Nottingham with “Do not go gentle’s” founder Olivia Aspinall.

The workshop was a chance to delve into material sustainability and circular design principles with a hands-on exploration of physical materials from Olivia’s library.

It was a fantastic opportunity to discuss big topics within the industry, share ideas and gain core material make up knowledge with other like-minded local designers. We covered topics such as waste utilisation, biomaterials, and material life cycles.

Sourcing and specifying materials

Through the workshop, Do-not-go-gentle’s approach to summarising the key facts to consider when specifying was to first understand material properties based on their source category.

Grown Materials

These are materials that can be grown naturally, for example, wool, linen, wood and bamboo. These are the materials we feel most connected to as humans, they are renewable and biodegradable, making them a sustainable choice when sourced responsibly.

Image Source Melle Lee Pinterest

This depends on agricultural practices, such as water usage, pesticide application, and land management. Certifications like FSC (Forest Stewardship Council) for wood and organic standards for textiles ensure that grown materials are produced in environmentally friendly and socially responsible ways.

There are a number of reasons to consider grown materials in our designs, not only for their natural benefits, but also because they are often far less toxic than their manufactured equivalents as they can be used in their raw state without any chemical treatment. This also means that they can be safely returned to their natural cycle and the end of their life.

We are finding a huge shift in raw and honest material processes being celebrated more frequently as the new luxury. The level of transparency in the design process and outcome now provides us, what we feel as designers, a great opportunity to celebrate the craftsmanship and a sense of story around a space or environment that has been created.

https://www.stellamccartney.com/gb/en/stellas-world/discover-23-old-bond-street.html

One of the stores that successfully blended this movement of raw, honest sustainability with luxury was Stella McCartney, when opening the London Bond Street store back in 2018. A firm favourite of ours still to this day. The balance of raw vs refined, and the architectural aim from the designers to create an intimate and emotional atmosphere, allowing consumers to interact very directly with the textures throughout the space just shows the importance of material choices in a project.

Bio & Recycled Materials

Biomaterials:

One of the newest advancements within the industry, described as a material derived from living organisms. A biomaterial includes plants, animals, and most commonly explored fungi, most specifically Mycelium.

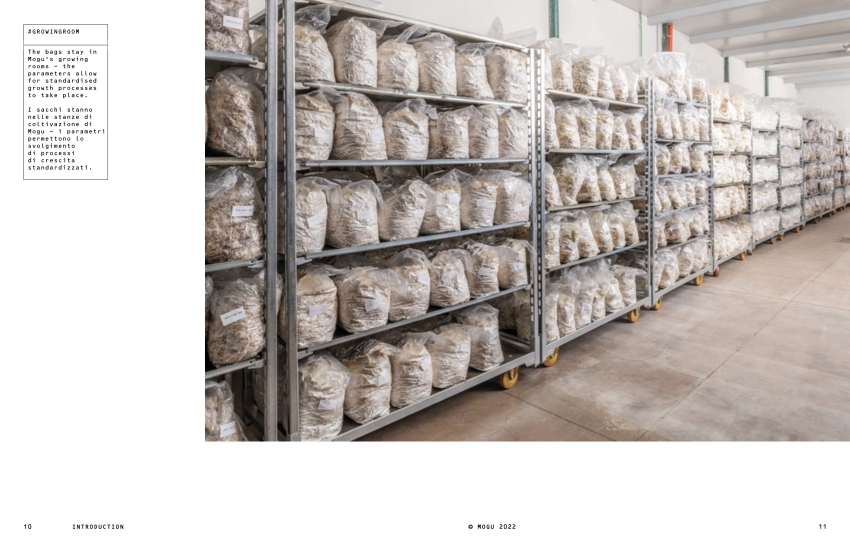

Talking recently to one of new material suppliers Nicholas Laughton from Material Hangout this week, the team were introduced to Italian based innovators Mogu.

Mogu Acoustic panels are the first commercially available products of their kind, entirely made of fungal mycelium and of upcycled textile residues.

Although raw biomaterials may not suit every application, we can still aim to reduce our carbon footprint with the use of recycled materials, the benefit of using a recycled material that have been responsibly remanufactured is their extended life, meaning a reduced impact over it’s entire lifecycle.

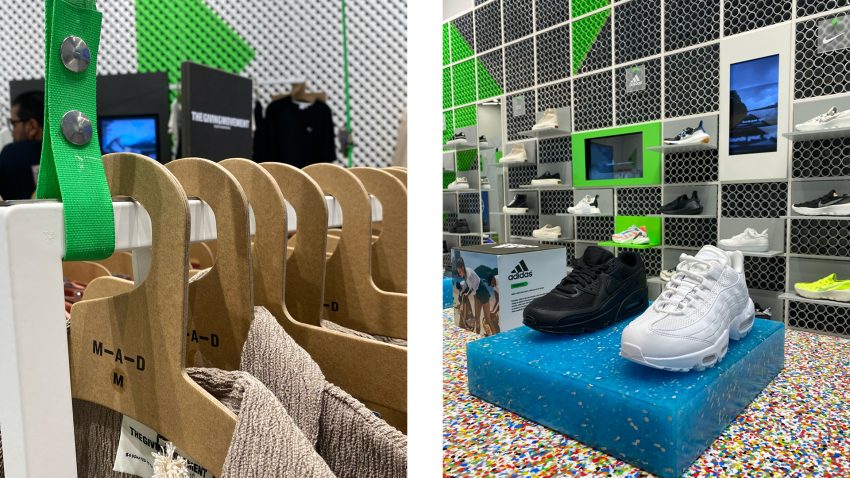

In the workshop, our 3D Team were introduced to a number of recycled materials that they are now able to consider in the design phase, for example board made from recycled denim. This material can be used as a sustainable replacement for plywood in most applications. Although manufactured, this material benefits from a reduced environmental impact, making use of waste denim.

Thanks to the materials versatility, using recycled plastics has the potential to vastly reduce the amount of waste plastic and it’s impact. The process used to create recycled plastic panels means that our designers can choose from a number of different colours and patterns. The material itself is also incredibly versatile, meaning we can create retail displays, counters furniture or even shower panels with great strength and durability.

Mono Materials

Mono Materials are materials made up of only one type of material. An example being cork, paper or plastic.

They are generally easier to reuse or recycle at the end of their life, as they do not need to be taken apart and require simpler recycling processes. Sometimes composites may be needed if a mono-materials does not contain all the qualities to serve a particular purpose.

Image source – SD Oxford Street Lifestyle Hub The One Off Recycled Cardboard Tubes as wall dividers

Although composite materials can be a great solution within our designs, we must ensure these are sourced responsibly by considering whether the original material is compostable or will biodegrade in a shorter time to give back to the earth and reduce its overall impact.

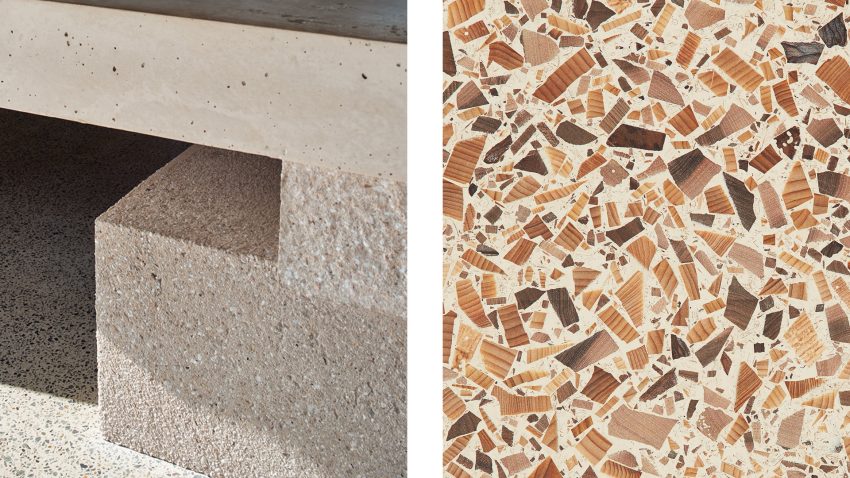

We have seen trends recently on composites being created to utilise waste by encasing the waste in bio-resins. This can be problematic, as it often means trapping organic matter inside a resin.

For example, using or embedding recycled wood chips into a non-sustainable solid surface such as an acrylic based resin, has now stopped those wood fibres from being recycled or composting therefore stopping the circular loop of that material. Depending on the second material properties within the composite, in general composite materials can be more difficult to recycle. Examples most commonly used recently in the world of retail design being Plywood and concrete.

Image Source Folk Architects Instagram Image Source Foresso Material https://foresso.co.uk

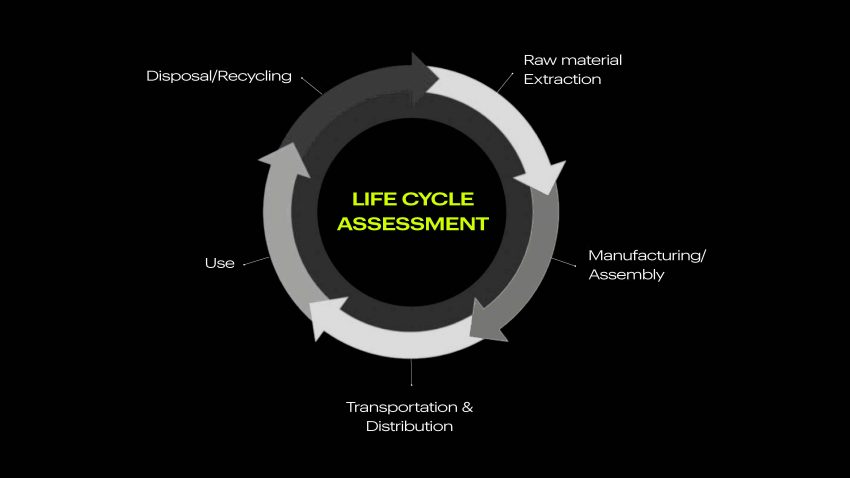

The Material Life Cycle

With every material we source we should consider it’s environmental impact. It is now possible to calculate this by the make-up of the material properties and evaluating what the full life cycle of that material is.

The longer the material life is, and its ability to be reused and recycled, usually the lower the carbon output of that item. We should therefore extend the products life beyond the design and build stages.

Key Outtakes

- Material passports

Creation of a material passport in the first instance ensures the materials’ circularity and its entire lifetime by holding the following data in an easily accessible central location including:

-Environmental credentials

-Demountability

-Health and Safety - Designing for disassembly

-Consider the materials’ second life.

-Avoid adhesives that spoil the finish of the material.

-Use fixings like screws, bolts and nails that can be easily removed without specialist tools.

-Use simple construction. - Waste utilisation

– Look within the existing space and consider the materials already used and how they can be creatively repurposed to extend their life. - Material end of life

-At the end of the materials life, will it biodegrade or recycle easily?

-If not, consider the longevity of the material, will it ever need to be replaced? Is it durable enough to live a second life?

How will we make our process more sustainable and responsible?

With retail being such a fast-paced industry and store concepts being rolled out and upgraded every few years, our mission as a team is to ask more questions when designing, learn from the experts and try to understand the construction restrictions to align with our contractors to ensure the build and install process is as easy as possible and the right material gets specified. We will also be considering a materials end of life and how that material may impact the environment after the project is finished, as our duty we feel if we are putting a material out there then we should have a plan for where it will end up.

Every designer and client is so different, we won’t always be able to control every step but designing with knowledge and sharing that knowledge to all involved within a project we know will make a huge impact. The current process does at times feel overwhelming but the transparency now between manufacturers through to designers and then to the build and contract teams is a unified expectation of the industry to do better, making asking those key questions much easier!

We hope our learnings and insights so far are inspiring and we look forward to sharing our journey as a team to this brighter, more sustainable future.